Exploring the Process of Custom Silk Production at a Silk Factory

Silk has long been considered a luxurious and highly sought-after fabric, known for its softness, sheen, and durability. Custom silk production at a silk factory involves a meticulous process that transforms raw silk into beautiful and unique silk scarves. From selecting the finest silk threads to dyeing and printing techniques, each step in the production process plays a crucial role in creating high-quality custom silk products.

| silk Herringbone | a scarf top | custom cotton handkerchief | cotton necktie company |

| custom wool blanket scarf | custom cotton Elastic Silk Hair Wraps | silk modal blend | beret |

The first step in custom silk production is selecting the raw silk material. Silk is a natural protein fiber produced by silkworms, and the quality of the silk is determined by factors such as the type of silkworm, the climate in which it was raised, and the diet of the silkworm. The silk threads are carefully extracted from the cocoons and then spun into yarns that will be used to create the fabric.

Once the raw silk material has been selected, the next step in the custom silk production process is dyeing the fabric. Dyeing is a crucial step that adds color and vibrancy to the silk fabric. Custom silk factories use a variety of dyeing techniques, including traditional methods such as hand-dyeing and modern techniques such as digital printing. The choice of dyeing method depends on the desired color and design of the final product.

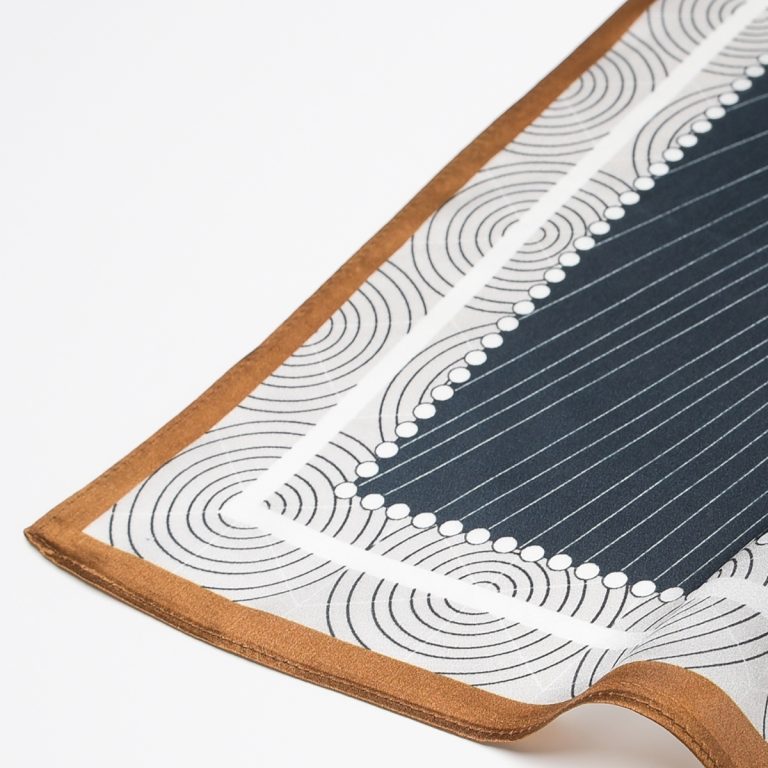

After the fabric has been dyed, it is ready for printing. Custom silk scarves can be printed with a wide range of designs, from intricate patterns to custom logos and images. Printing techniques such as screen printing, digital printing, and block printing are used to transfer the design onto the silk fabric. Each printing method has its own unique advantages and can create different effects on the fabric.

Once the fabric has been dyed and printed, it is time to finish the custom silk scarf. Finishing techniques such as hemming, fringing, and hand-rolling are used to give the scarf its final touch. These finishing touches not only add to the aesthetic appeal of the scarf but also ensure that it is durable and long-lasting.

Custom silk production at a silk factory requires a high level of skill and expertise. Silk artisans who work in custom silk factories have years of experience in working with silk and are trained in the various techniques used in silk production. From selecting the raw silk material to dyeing, printing, and finishing the fabric, each step in the production process is carried out with precision and attention to detail.

In conclusion, custom silk production at a silk factory is a complex and intricate process that involves multiple steps and techniques. From selecting the raw silk material to dyeing, printing, and finishing the fabric, each step plays a crucial role in creating high-quality custom silk products. Silk artisans who work in custom silk factories have the skill and expertise to transform raw silk into beautiful and unique silk scarves that are sure to impress. Whether you are looking for a custom silk scarf for yourself or as a gift for someone special, custom silk production at a silk factory is the perfect way to create a one-of-a-kind accessory that is both luxurious and stylish.